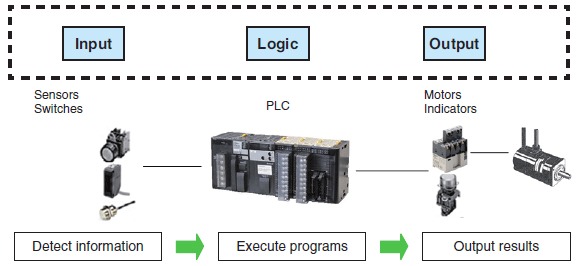

Figure 1: A programmable logic controller(Source: OMRON )

Types of PLCs available across the industries

PLCs are available in different subcategories, with each subcategory designed to meet the unique requirements of a particular process and industry. The following types of PLCs are available based on their capabilities and other features:

- Compact PLC: A compact PLC is a space-efficient and cost-effective solution for small-scale users. It has a small form factor with fixed I/O capability determined by the manufacturer. Compact PLCs have an integrated power supply, CPU, I/O interfaces, and other components housed in a condensed chassis. They are cheaper and are suitable for basic control requirements. However, they can be a challenge to repair and troubleshoot.

- Modular PLC: A modular PLC has a separate module for each hardware component. These PLCs have different modules, like a power supply module, I/O modules, and a CPU module, plugged together on the same bus. Modular PLCs are of different sizes and have varying power supply rates and computing capabilities. This type of PLC is suitable for large-scale projects and easy to troubleshoot and repair.

- Soft PLC: A Soft PLC, or Software-based Programmable Logic Controller, is a virtualized control system that runs on general-purpose computer hardware. Unlike traditional hardware-based PLCs, soft PLCs use software programs to emulate the functionality of a PLC. These PLCs combine the functions of conventional PLCs with those of data loggers, communications gateways, and other elements such as HMIs and web servers. Soft PLCs offer flexibility and scalability, allowing users to deploy control logic on standard industrial computers or embedded systems. They are often used in applications with limited hardware space, or the control system must run on existing computing infrastructure. Soft PLCs are easy to program, can be accessed remotely, and can be integrated with third-party software applications in industrial automation settings.

- Safety PLC: A Safety PLC is a particular type of PLC designed to ensure the safety of industrial processes and machinery. A safety PLC supports all the applications that a standard PLC does. It has advanced safety features and meets IEC 61508 and IEC 61511 standards. Safety PLCs have redundancy, self-monitoring capabilities, and fail-safe mechanisms to detect and respond to potentially hazardous situations. They are critical in implementing safety functions, such as emergency shutdowns, machine guarding, and process integrity.

- OpenPLC: An OpenPLC is an open-source PLC based on easy-to-use software. It is the first fully functional standardized open-source PLC in software and hardware. The OpenPLC runs on Raspberry Pi, Arduino, UniPi, and as a soft-PLC on Windows or Linux. It uses OpenPLC Editor, software on a computer, to create your PLC programs. It is simple to use and supports all five languages defined in the IEC 61131-3 standard.

PLC programming Languages

You can use the following programming languages to program PLCs. These languages are defined in the IEC 61131-3 standard:

- Ladder Logic, or ladder diagram (LD), is the most traditional and widely used programming language for PLCs. It is a symbolic depiction of instructions arranged in rungs like ladder-formatted schematic diagrams. Ladder logic is easy to understand, and its graphical nature makes it easy to understand and debug code.

- Function Block Diagram (FBD) uses simple and complex interconnecting blocks to represent process flows graphically. It is like Ladder Logic but can be more modular and is often used for complex control applications. Predefined function blocks are used primarily for repetitive tasks and control systems to reduce development time and improve maintainability.

- Sequential Function Chart (SFC) graphically depicts interconnecting steps, actions, and transitions. It helps describe complex processes with multiple steps and stages. The SFC programming language can simplify a complicated process by dividing it into more manageable tasks. It makes the programming easier to test, understand, and troubleshoot issues.

- Structured Text (ST): is a high-level programming language like C or C++. It allows for more complex programming structures like loops and conditional statements.ST is best suited for more complex control algorithms and mathematical operations. It also helps create reusable code modules that save time and reduce errors.

- Instruction List (IL): It is a low-level, text-based programming language that resembles assembly language. It uses mnemonic instructions to represent specific operations. This programming language is less common than Ladder Logic or Structured Text but can be helpful in certain situations.

Criteria for selecting the right PLC for application

It would help if you considered the following factors for PLC selection for a particular operation:

- Process Requirements: It covers the specific needs of your automation application. This includes factors like the complexity of the control system, the number of loops to be controlled, the number of time-critical events, the operation speed of the process or machine, and the communication interfaces needed. The selected PLC should be able to handle the current and future demands of the process.

- Input/output (I/O) Capability: I/O capacity denotes the quantity of input and output signals a processor can manage. Determining the necessary I/O signals depends on the number of devices within the process that require control or monitoring. PLCS should incorporate sufficient margins for I/O points. Typically, by augmenting the calculated I/O point statistics with an additional 10 percent to 20 percent for expandable margins, an estimated count of input/output points can be derived. However, when proceeding with actual orders, adjustments to the input/output point count must be made, considering the specific characteristics of the manufacturer's PLC product.

- Memory and Processing Speed: The processing power of a processor dictates the speed at which the control tasks are executed and the response to I/O signals. The performance of PLC depends on the processing power. Memory is another essential factor when selecting a processor for your PLC hardware. Memory stores the data and programs, and the processor executes them. The amount of memory required depends on the complexity of control functions and the size of the programs.

- Power Supply: The specifications outlined in the product manual must match the PLC's power supply selection and design. Industrial PLCs commonly function on either 120-volt or 240-volt AC. The PLC's power supply steps down this AC and transforms it into a 24-volt DC. While some power supplies are integrated into the processor, others are accommodated in a distinct module outside the PLC casing or connected through hardwiring.

- Communication Protocol: Connectivity plays a crucial role in PLC operation. The reliability and speed of the communication network are essential for PLC system operation. When designing, the designer must evaluate the communication options of the PLC and seek a product that supports a diverse array of communication protocols and interfaces, including Ethernet/IP, Modbus, DeviceNet, Profibus, or OPC-UA. Furthermore, compatibility with the current or anticipated network infrastructure is essential for smooth integration with devices like HMIs, SCADA systems, or third-party systems.

- Programming: You should select a PLC depending on the programming languages it supports and the accompanying programming software. Ensure that, in the implementation phase, the programming language chosen is comfortable to programmers or commonly used in your organization. This will increase efficiency. The programming characteristics of the chosen PLC should be such that they can be quickly developed, troubleshot, and maintained.

- Scalability: As the needs of automation may change or expand over time, it is necessary to upgrade the PLC device to satisfy those new demands. The designer should look for scalability to ensure the automation system can adapt to future requirements without requiring a complete overhaul. Choosing a PLC that supports additional I/O modules or memory expansion ensures the system can effectively manage increasing processes and equipment.

- Compatibility: The selected PLC must be compatible with the existing systems and equipment in the facility, including communication protocols, I/O modules, and other components. Incompatible components can cause the system to malfunction, potentially leading to safety hazards and increased downtime.

- Safety and Security: When designing a PLC, the top priorities should be safety and security. The PLC must incorporate integrated safety functions to prevent failure; if failure is inevitable, it should ensure a safe failure. In terms of security, any bugs or vulnerabilities must be promptly identified and resolved. The PLC must be secure and reliable to mitigate the risks of cyber-attacks or data breaches. Additionally, the system should incorporate multiple layers of security to guarantee secure communication.

- Support and Service: The ability of the manufacturer to offer after-sales technical support and service is an essential consideration during PLC selection. Choose a PLC from a manufacturer offering comprehensive technical support, training, and maintenance programs for smooth operation and troubleshooting. It prevents any potential operational challenges during the PLC's deployment.

Correct I/O module selection for PLC

The technical specifications and the overall economic considerations of the intended solution should influence the I/O module type selection. A few common types of I/O modules, along with the necessary specifications, are:

- Digital I/O module: It connects field input devices with ON/OFF characteristics, such as selector switches, pushbuttons, and limit switches. Output control is limited to devices such as lights, relays, solenoids, and motor starters that require simple On /Off type switching. The classification of discrete I/O covers bit-oriented inputs and outputs. In this type of input or output, each bit represents a complete information element and provides the status of some external contact or the presence or absence of power in a processing circuit. A field-supplied voltage source powers each discrete I/O module. Since these voltages can be of different magnitudes or types, I/O modules are available at various AC and DC voltage ratings. The modules themselves receive their voltage and current for proper operation from the backplane of the rack enclosure into which they are inserted. The PLC module power supply provides backplane power. It is used to power the electronics on the I/O module circuit board—the relatively higher currents required by the output loads.

- Analog I/O module: Analog input modules can be divided into current input type, voltage input type, thermocouple input type, etc., according to the type of analog input signals. Compared to discrete I/Os that have only two states, on and off, analog devices represent physical quantities that can have an infinite number of values. Typical analog inputs and outputs vary from 0 to 20 mA, 4 to 20 mA, or 0 to 10 V. The analog input interface module contains the circuitry necessary to accept an analog voltage or current signal from the level transmitter field device. This input is converted from an analog to a digital value for use by the processor. The analog output module's circuitry accepts the processor's digital value and converts it back to an analog signal that drives the field device. Analog input modules typically have multiple input channels that allow 4, 8, or 16 devices to be interfaced to the PLC. The two basic types of analog input modules are voltage sensing and current sensing. Analog sensors measure a varying physical quantity over a specific range and generate a corresponding voltage or current signal. A PLC analog module's standard physical quantities measure temperature, speed, level, flow, weight, pressure, and position. For example, a sensor may measure temperature from 0 to 500°C and output a corresponding voltage signal between 0 and 10 V.

- Special I/O modules: Specific applications, such as motion control, safety, and communication, use these specialty modules. For example, applications that involve motion and position control modules need accurate high-speed machining and packaging. Process control applications use the proportional-integral-derivative (PID) module with PID algorithms. The user can harness the communication modules to connect the PLC to high-speed local networks. Such a connection may differ from the PLC-provided network communication.

PLC installation practices and wiring process

The controller can operate trouble-free in any environment if the best PLC installation practices and wiring processes are followed. Best practices help save time and effort for the systems designer or installer. Some of the best PLC installation and wiring processes are:

- Enclosures: An enclosure protects the electronics from moisture, oil, dust particles, and unwanted tampering. Most manufacturers recommend a NEMA 12 enclosure for the standard industrial environment or a NEMA 4X for outdoor or corrosive environments. Metal enclosures provide shielding that helps minimize the effects of electromagnetic radiation generated by surrounding equipment.

- Safety considerations: Emergency stop circuits must be in place for each machine directly under PLC control within the system. A hardwired electromechanical master control relay (MCR), shown in Figure 2, is usually included as part of the wiring for a PLC system. This MCR offers a mechanism to de-energize the entire circuit independently of software. In an emergency, the hardwired MCR is linked to interrupting power to the I/O rack while maintaining control of the processor.